- Flexible Design. 3D printing allows for the design and print of more complex designs than traditional manufacturing processes. ...

- Rapid Prototyping. ...

- Print on Demand. ...

- Strong and Lightweight Parts. ...

- Fast Design and Production. ...

- Minimising Waste. ...

- Cost Effective. ...

- Ease of Access.

What are the advantages and disadvantages of 3D printers?

FDM Printing Advantages & Disadvantages | Detailed

- Main Advantage & Disadvantage of FDM 3D Printing. FDM Printers cost-to-production ratio is very good, at a minimal cost they can print very large models, that too very effectively.

- Advantages & Disadvantages of FDM In A Nutshell

- FDM Printing Advantages In Detail. ...

- FDM Printing Disadvantages In Detail. ...

What are the major uses of 3D printing?

- Laser Beam Melting

- Photo Polymerization

- Electron Beam Melting

- Droplet Deposition

- Three-Dimensional Printing (3DP) By Component [Value ($ Million) from 2015 – 2026]:

- Equipment

- Materials

- Plastic

- Ceramic

- Metal

What are the dangers of 3D printing?

The dark side of 3D printing: 10 things to watch

- 3D printers are energy hogs. When melting plastic with heat or lasers, 3D printers consume about 50 to 100 times more electrical energy than injection molding to make an ...

- Unhealthy air emissions. 3D printers may pose a health risk when used in the home, according to researchers at the Illinois Institute of Technology.

- Reliance on plastics. ...

What are some good things to 3D print?

67 Cool Things to 3D Print

- 3DBenchy. The 3DBenchy appears to be nothing more than an adorable plastic boat, but it’s more than that. ...

- Survival Whistle. ...

- Sunglass Visor Clip. ...

- Earbud Case. ...

- Carabiner. ...

- Flexi Rex. ...

- Key Holder. ...

- Pencil Holder. ...

- Headphone Stand. ...

- Bowl. ...

How 3D printing can benefit society?

Benefits to society 3D printing leads to a reduction of wastes and thus, there is no requirement of reducing, reusing, and recycling the waste materials every now and then.

What are the pros and cons of 3D printing?

We talked to three professionals in the 3D printing sphere, including Mages, about the pros and cons of the technology.PRO: MAKES MAKING EASY.CON: INEFFICIENT FOR LARGE BATCHES.PRO: ALLOWS FOR NEW SHAPES.CON: PRINTING MATERIALS POSE CHALLENGES.PRO AND CON: IMPACTS JOBS.PRO: ECO-FRIENDLY.CON: REGULATORY CHALLENGES.

Who can benefit from a 3D printer?

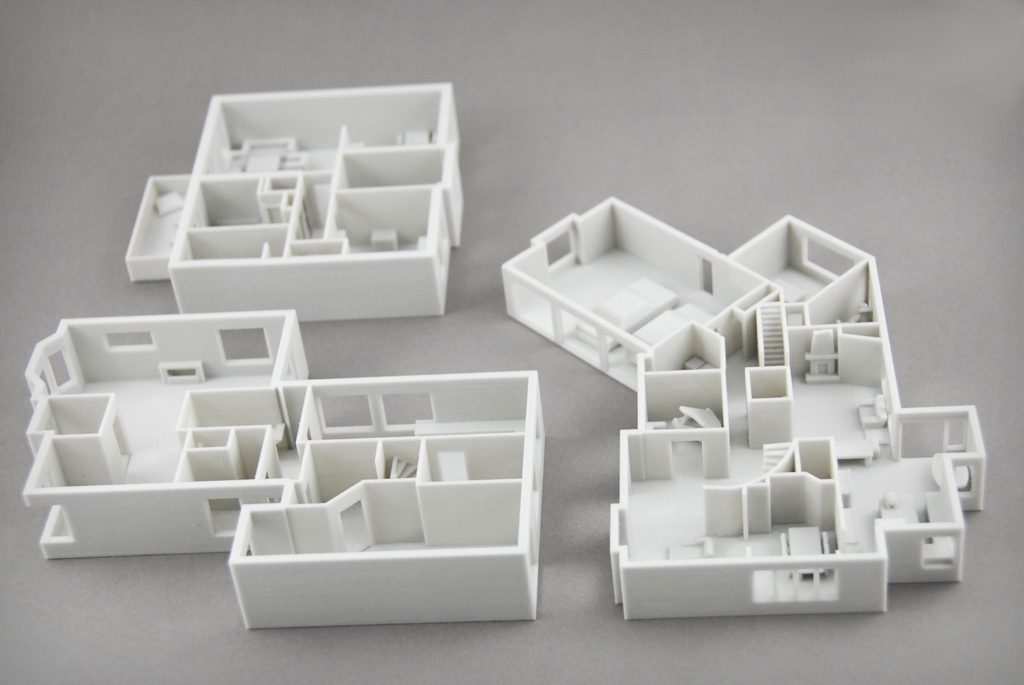

Main benefits of 3D printingAllows you to quickly test your ideas. It can take months for engineers, architects, designers and educators to create concepts and test models in the traditional way. ... Continual designs. ... Real materials and real parts. ... Hands-on learning. ... Saving costs. ... EDUCATION. ... MEDICAL CARE. ... DENTAL.More items...

What are 5 benefits of 3D printing?

The five benefits of 3D printing.The five benefits of 3D printing. ... Save on tooling costs with on-demand 3D printing. ... Reduce waste with additive manufacturing. ... Improve lives, one customized part at a time. ... Save weight with complex part designs. ... Reap the benefits of 3D printing.

Why is 3D printing important for the future?

3D printing can produce parts, allow for changes without requiring extra tools or equipment in comparison to other methods. The future possibilities are exponential and this is why the world is fixated on the technology. 3D printing turns the head on standard manufacturing.

What are the advantages of 3D environment?

One of the most important potential learning benefits of 3D environments is in developing an understanding of the complex systems we encounter in the world, such as the environmental ecosystem, physical and electrostatic forces, or the intricate workings of a machine.

What problems does 3D printing solve?

Solving the Top Engineering Problems with 3D Printing1) SPEED AND LEAD TIME. Quality manufacturing takes time. ... 2) COST REDUCTION. ... 3) RISK MITIGATION. ... 4) DESIGN FLEXIBILITY. ... 5) MATERIALS & SUSTAINABILITY.

How is 3D printing improving people's lives?

3D printing will be used to create anatomical structures in cell cultures to imitate the growth of human organs. It will save countless lives by allowing faster transplants, compatible without the need of lifelong anti-rejection treatments.

Is 3D printing expensive?

3D printing can cost anywhere from $3 up to thousands of dollars. It's hard to get the exact cost of a 3D print without a 3D model. Factors such as material, model complexity, and labor affect the price of 3D printing. 3D printing services can sometimes cost more than an entry level 3D printer.

What was the most interesting thing about 3D printing?

8 Interesting Facts about 3D Printing3D printers print a model in layers. ... You can already print in titanium, ceramics, wood, etc! ... 3D printing can lower production costs. ... 3D printing is in the movies you watch. ... 3D printing is launching into space. ... 3D printing is being used for education.More items...•

How many 3D printers were sold in 2016?

In 2016, over 275,000 3D printers were sold worldwide according to Wohler’s yearly report. Projected growth shows that 3D printing will ultimately generate more than $21 billion in revenue across the globe. Using 3D printing technology can provide numerous benefits both for individuals and businesses alike.

How long does it take to make a 3D printer?

3D printing production takes just hours. Conversely, testing ideas and designs with conventional manufacturing methods can take up days, if not several weeks. 2. Easily Accessible.

Can mass manufacturing be used for 3D printing?

Product designers have to keenly calculate their steps when it comes to materials to use with either subtractive or injection mold manufacturing. Mass manufacturing doesn’t support the blending of raw materials as it can be expensive. Furthermore, combining chemical and physical elements is complicated. 3D printing easily accommodates a diverse range of raw material including glass, metal, paper, ceramics, biomaterial, silver, etc.

Is traditional manufacturing good?

Traditional manufacturing techniques are good at creating millions of copies of the same thing. It results in same dull and boring designs without the capacity to be improved much. Making each design unique with these techniques is extraordinarily hard.

Is 3D printing faster than conventional manufacturing?

3D printing is quicker than conventional manufacturing including injection molds and subtractive production. Think the speed of a sports car versus the speed of a horse cart. Both will reach their destination, but the time difference is significantly huge. From a prototype to a final product, 3D printing tests ideas and designs quickly.

Why is 3D printing important?

3D printing enables you to design a concept and make it a reality faster than anything else. Due to the speed and lower cost of 3D printing, it’s also a less risky process. Even small changes to a mold or CNC process can increase the production cost and time. You can be confident your 3D printed design is a production-ready prototype before investing in expensive manufacturing equipment or processes.

Is 3D printing an additive process?

Because 3D printing is an additive process, the production only requires materials built into the part itself. There’s little to no waste compared to the subtractive processes that can leave large pieces of material and require long cleanup times.

What are the advantages of 3D printing?

One of the biggest advantages of 3D printing technology is Rapid Prototyping. Rapid prototyping is the ability to design, manufacture, and test a customized part in as little time as possible. Also, if needed, the design can be modified without adversely affecting the speed of the manufacturing process.

Why is 3D printing good for the environment?

This equals less environmental impact because fewer things are being shipped across the globe and there is no need to operate and maintain an energy-consuming factory.

What is 3D printing?

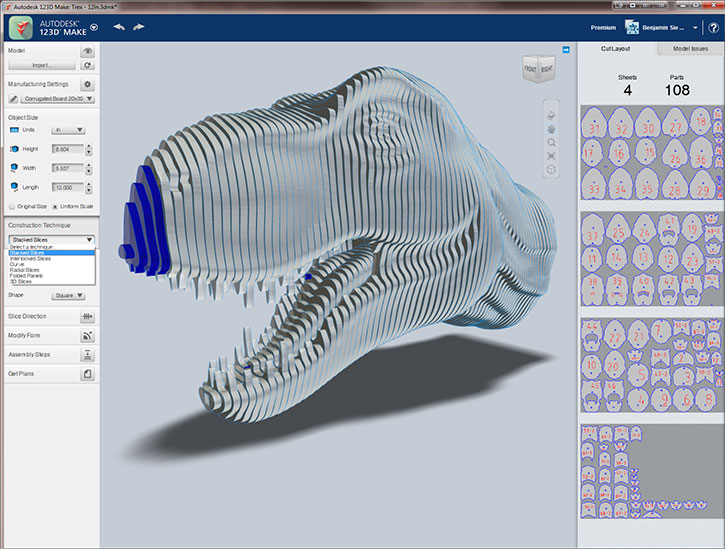

3D printing allows the creation and manufacture of geometries impossible for traditional methods to produce, either as a single part, or at all. Such geometries include hollow cavities within solid parts and parts within parts. 3D printing, in contrast to traditional methods, allows the inclusion of multiple materials into a single object, ...

How long does it take to make a 3D printer?

Before 3D printing industry came to flourish, a prototype would take weeks to manufacture. Every time a change was made, another few weeks of time were added to the process. With shipping times figured in, fully developing a product from start to finish could easily take a year.

How is 3D printing made?

As the name suggests, parts are produced by injecting heated material into a mold. So, what is 3D printing? Additive manufacturing, aka 3D printing, is the process of producing 3-dimensional objects from a computer file, where the part is built by adding material layer-by-layer.

Why is 3D printing competitive?

Competitive Advantage. Because of the speed and lower costs of 3D printing, product life cycles are reduced. Businesses can improve and enhance a product allowing them to deliver better products in a shorter amount of time.

Is 3D printing more expensive than traditional manufacturing?

3D printing systems are much more accessible and can be used by a much wider range of people than traditional manufacturing setups. In comparison to the enormous expense involved with setting up traditional manufacturing systems, a 3D printing setup costs much less.

Why is 3D printing important?

It is all because of the plethora of benefits additive manufacturing offers. One can do things that were not possible before and it’s all because of 3D printing. The benefits of 3D printing have led it to become a worldwide phenomenon. Starting from the gift shops to the high-end production of aerospace parts, 3D printing has booked its space in ...

Why are people using 3D printers?

The people around the globe are using 3D printers to create amazing designs and items that were impossible to manufacture. The intricate design and finer details are well carved with the help of 3D printers without a need for too many hands. ADVERTISEMENT.

How is 3D printing used?

3D printing is being used by individuals around the world for various tasks. The cheaper and smaller desktop machine has a smaller learning curve and can be used inside houses as well.

Is 3D printing a good idea?

3D printing is a boon for printing small parts at the fastest speed. Especially while prototyping, 3D printing is the best option. With traditional manufacturing, one has to create casts and molds to design a prototype.

Can you print a part from a 3D printer?

However, with 3D printing, one 3D printer can add layer one over another to print the part directly from the 3D printers. ADVERTISEMENT.

Can you 3D print a blueprint?

However, with 3D printing, one can design the 3D print and can use a 3D printer to print the part in a matter of hours or days. The changes are easy to incorporate. By changing the blueprint, one can implement the suggested changes to the prototype.

Can you print prototypes faster?

Not just that one can design the prototypes faster, one can print is exactly as designed in the first go itself without involving much cost and effort. And, in lesser time. Even in need for design change, there won’t be much loss in terms of cost and time. This significantly reduces the risk of failure.

What are the advantages of 3D printing?

1. Flexible Design. 3D printing allows for the design and print of more complex designs than traditional manufacturing processes. More traditional processes have design restrictions which no longer apply with the use of 3D printing. 2.

Why is 3D printing so cost effective?

Cost Effective. As a single step manufacturing process, 3D printing saves time and therefore costs associated with using different machines for manufacture. 3D printers can also be set up and left to get on with the job, meaning that there is no need for operators to be present the entire time.

How does 3D printing help the environment?

10. Advanced Healthcare. 3D printing is being used in the medical sector to help save lives by printing organs for the human body such as livers, kidneys and hearts.

Why is 3D printing so bad?

Another potential problem with 3D printing is directly related to the type of machine or process used, with some printers having lower tolerances, meaning that final parts may differ from the original design. This can be fixed in post processing, but it must be considered that this will further increase the time and cost of production.

How fast can 3D printing be?

5. Fast Design and Production. Depending on a part’s design and complexity, 3D printing can print objects within hours, which is much faster than moulded or machined parts.

What is the best material to use for 3D printing?

The main 3D printing material used is plastic, although some metals can also be used for 3D printing. However, plastics offer advantages as they are lighter than their metal equivalents. This is particularly important in industries such as automotive and aerospace where light-weighting is an issue and can deliver greater fuel efficiency.

Why is print on demand important?

Print on demand is another advantage as it doesn’t need a lot of space to stock inventory, unlike traditional manufacturing processes. This saves space and costs as there is no need to print in bulk unless required.