- You will decrease waste. Six Sigma ideology is aimed to help you and your company optimize processes to decrease your total waste. ...

- You will increase efficiency. ...

- You will reduce errors. ...

- You will reduce your company's legal risk. ...

- You can apply it to any industry. ...

- You will make more money.

Financial benefits

Six Sigma as a path breaking methodology for the business improvement has its own advantages and disadvantages. Advantages : (1) Six Sigma is driven by the customer and thus aims to achieve maximum customer satisfaction and minimizing the defects. It targets the customer delight and new innovative ways to exceed the customer expectations.

Strategic benefits

- Reduce time required to design a product or service

- Reduce errors in design or find them earlier in development

- Reduce estimated production cycle times

- Improve predictions of capability and risk of new products and services

- Reduce testing and inspection time

- Reduce software bugs in programming code

People development benefits

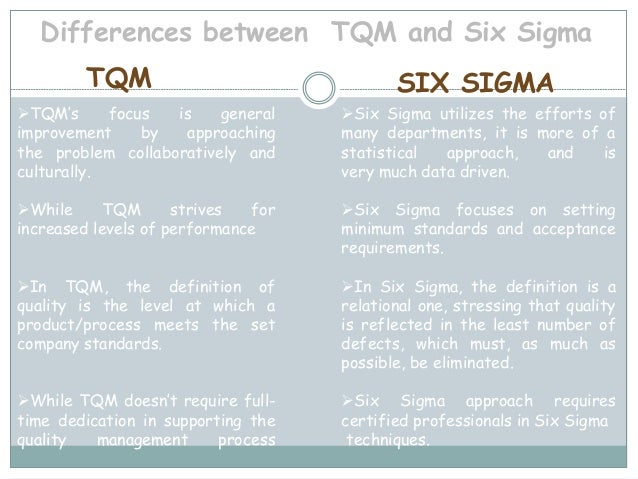

Six Sigma is another process improvement methodology that aims to systematically and continually optimize processes. Like lean, many of its benefits include: However, whereas lean focuses on waste reduction, Six Sigma focuses on reducing variation and defects.

Customer benefits

Why Lean Six Sigma Training Is Important for Your Business Growth

- Fewer Errors and More Productivity. As mentioned earlier, Six Sigma gives your organization the benefit of smoother operations and improved results on your current processes.

- Workforce Empowerment. ...

- Methodical Use of Resources. ...

- Reduce Production Costs. ...

- Earn More Customers. ...

- You Learn to Lead and Influence People. ...

- To Sum It Up. ...

Competitive advantage

What are the advantages and disadvantages of Lean Six Sigma?

What makes a bad Lean Six Sigma project?

Which is better, lean or Six Sigma?

What is Lean Six Sigma and why is it important?

What are the benefits of using Six Sigma?

Here are 12 benefits of utilizing Six Sigma:Career Advancement. ... Helps Nurture Managerial and Leadership Ability. ... Standardization. ... Improve Business Processes and Sustain Quality Improvement. ... Excellent Salary. ... Applicability across Industries. ... Ensure Compliance. ... Gain Hands-On Experience in Quality Management.More items...•

What are the benefits of lean?

Lean manufacturing improves efficiency, reduces waste, and increases productivity. The benefits, therefore, are manifold: Increased product quality: Improved efficiency frees up employees and resources for innovation and quality control that would have previously been wasted.

How useful is Lean Six Sigma?

Six Sigma-certified professionals can use statistical analysis to increase efficiency and reduce waste. Consequently, this methodology can save organizations money, improve morale and performance, and elevate product quality. Here's a closer look at what Six Sigma is and what certifications you can earn.

Why is lean important to study?

The principles of Lean are designed to boost the productivity and efficiency of essential business processes, resulting in more refined production cycles. Crucially, however, the same principles emphasize the importance of retaining the quality of end products.

What is the focus of Six Sigma?

The Six Sigma method is focused on limiting fluctuation within business processes and quality management of process output by implementing problem-solving statistical methods. Conversely, the primary focus of Lean Six Sigma is to eliminate waste and improve existing processes.

What are the advantages and disadvantages of Six Sigma?

The main advantage of Six Sigma compared to other approaches to quality control is that Six Sigma is customer driven. Six Sigma is defined as a limit of 3.4 defects per one million products or service processes, where anything not acceptable to the end customer is considered a defect.

What are the 5 principles of lean?

According to Womack and Jones, there are five key lean principles: value, value stream, flow, pull, and perfection.

When should I use lean?

Like any other Agile methodology, Lean can succeed in small projects with a short time frame. That can be explained by the fact that Lean teams are small. It is quite hard for them to manage large projects quickly. You have to coordinate the activities of two or more Lean teams, if you want to handle a big project.

What are the benefits of lean product development?

10 Benefits of Lean Product Development#1: Reduces waste. ... #2: Improves results. ... #3: Speeds creation. ... #4: Empowers stakeholders. ... #5: Provides flexibility. ... #6: Streamlines production. ... #7: Builds knowledge. ... #8: Simplifies error tracking.More items...•

What are the main benefits of a lean system quizlet?

Some of the benefits of lean production are reduce inventory, improve quality, and lower costs. Reduction of inventory is a benefit of lean production because the idea is to eliminate waste. The less waste, the less inventory that is needed in order to make a product or perform a service.

Lean Six Sigma Increases Profit

Lean Six Sigma increases your organization’s profit by streamlining processes.Streamlined processes result in products or services that are complet...

Lean Six Sigma Decreases Costs

Lean Six Sigma decreases your organization’s costs by: 1. Removing “Waste” from a process. Waste is any activity within a process that isn’t requir...

Lean Six Sigma Improves Efficiency & Effectiveness

Lean Six Sigma improves the efficiency of your organization by: 1. Maximizing your organization’s efforts toward delivering a satisfactory* product...

Lean Six Sigma Helps Develop Effective People & Teams

Lean Six Sigma develops effective employees within your organization by: 1. Involving employees in the improvement process. This promotes active pa...

What is Lean Six Sigma?

Lean Six Sigma is a bedrock of transformation programs today with Black Belts and Master Black Belts at the heart of driving that transformation program. The biggest benefits of Lean Six Sigma training and certification is that it equips you to be better placed to help drive, support and lead strategic projects to form both a local level ...

What is the fundamental to lean and six sigma?

As part of the Fundamental to Lean Six Sigma workshop, there is a crucial focus on two key elements. From an analytical thinking point of view, lean and six sigma methodologies provide a toolbox to help break down complex problems into manageable components.

Is there a correlation between operational excellence and measures of strategic success?

Thirdly, HBR research also identified that there is a strong correlation between operational excellence and measures of strategic success. So businesses which ignore the impact of their processes on their results will find that brilliant leadership is no longer enough.

Why is Lean Six Sigma important?

While Lean Six Sigma helps your business increase its profits, on the flipside, it also enables you to run your business with a much more cost-effective strategy.

Why is Lean Six Sigma so successful?

The number one reason why Lean Six Sigma and its Six Sigma counterpart have been so successful is because the programs are based upon one huge factor: increasing efficiency.

How does Lean Six Sigma work?

Lean Six Sigma has been proven to improve business processes from the inside out, streamlining those processes to increase efficiency and enabling your business to sell, manufacture, and provide services fast er and more cost-effective. Increases Revenue.

What is the name of the program that improves business processes?

After the dramatic success of the Six Sigma program took the business world by storm, the developers of Six Sigma came out with an even more personalized approach to improving business processes: Lean Six Sigma.

Is Lean Six Sigma easy to learn?

It's Easy to Use. Last but not least, Lean Six Sigma is a program that is easy to learn and easy to implement. The program is divided into various stages, with each stage corresponding to a certain level ...

Why is Lean Six Sigma important?

All businesses that care about growth need scalable processes. Lean Six Sigma optimizes processes and documents them. This helps you reclaim your intellectual and automation resources and revenue from your business. Then it easy to perform, learn, enhance, and operate for faster expansion.

What is Lean Six Sigma?

Lean Six Sigma (a combination of Lean methodologies and Six Sigma strategies) is just one business methodology that is more essential today than ever before increasing the capabilities to survive in a volatile and rapidly changing environment. Granting your business the capability to ensure prompt delivery methods, decrease waste, and solidify superior products/services for your customers, Lean Six Sigma can make any organization adept at overcoming the toughest challenges so that you can take advantage of your most profitable opportunities.

What are the principles of Lean Six Sigma?

The principles of Lean and Six Sigma place the customer at the center of process creation and improvement. They will help you define who your customer is and pinpoint their expectations. This is the value that all your processes should aim to create in production. Lean Six Sigma principles will also analyze and optimize value to elevate the customer’s experience.

How does Six Sigma impact a company?

Lean Six Sigma positively impacts your business by increasing your capacity to carry out your processes while reducing your employee’s world per unit in production. This means you can literally do more with less. Your production will speed up while your quality standards continue to improve.

How does leaning help your business?

It will enhance problem-solving, infusing your business with a more proactive approach, rather than a reactive one. If you remove poor inspect-and-rework cycles, you will save resources and enjoy a better reputation with all your stakeholders.

How does Lean Six Sigma benefit the economy?

The financial benefits of Lean Six Sigma are large and well documented. Companies dedicated to implementing Lean Six Sigma not only see increased profits by reducing expenses, but can also benefit from an increase in revenue. For example, at North Shore-Long Island Jewish Health System, a radiology throughput project not only helped meet ...

What is Lean Six Sigma?

Lean Six Sigma is a methodology and toolset that combines all the benefits of Six Sigma with those of Lean enterprise, so you can find the right tool for every job. Its aim is to identify and systematically remove defects and waste from every process within a company, organization or entity – in any industry, segment and business size. ...

Does Six Sigma improve the bottom line?

Employee Satisfaction Benefits. Six Sigma doesn’t just improve the top and bottom line for your company, which shareholders love. Six Sigma employees themselves attest to improved job satisfaction. One of the core tenets of Lean Six Sigma is to stop relying on the intuition and gut feel of managers to make the right steps for business operation ...

Is Lean Six Sigma a good investment?

The potential benefits for a company that embarks on a Lean Six Sigma initiative make it a worthwhile investment. Though you can start to see results from the first year, the financial benefits grow as employees experience a culture change and take initiative to identify and eliminate waste. And while Lean Six Sigma is not easy to implement, it is ...

Why is Six Sigma important?

Six Sigma projects help improve the efficiency of the overall process. Moreover; improving the timelines in delivering the process output or improving the on-time delivery of products or service every time can be the focus areas for Six Sigma projects.

What is Six Sigma used for?

It has been popularized by Jack Welch and others and was even used by the U.S. government to fight the war on terror. The point to be considered here is that Six Sigma methodology has served diverse customer bases. Bases that are across different parts ...

What is Six Sigma inspection?

In case of such projects, the flow or process would be set up such that any potential errors will be captured & fixed at the process step where they occur. Six Sigma is a Quality Assurance methodology. The six sigma project should be aimed towards preventing the inspection function by delivering the right output at once.

Who is Nilesh from LEAN Six Sigma?

Nilesh is a commerce graduate from Mumbai University. He is LEAN Six Sigma Master Black Belt certified and currently; he is working as an independent LEAN Six Sigma Trainer & Consultant. In his current role, he caters to the Process Excellence & Training needs of a variety of clients operating in IT, ITeS, Manufacturing, and other prominent industries. Nilesh has around 16 years of experience in conducting LEAN & Six Sigma initiatives. He has led, coached & mentored 95+ improvement projects that delivered QNS to the tune of USD 109 million+. He has also delivered 135+ Live Virtual Classes (LVCs) and 110+ Recorded Virtual Classes (RVCs) for professionals in the US, North America, and Europe.

What are the three aspects of regulatory compliance?

Normally, there are three aspects of regulatory compliance. The first one is Finance & Audit, the second one is Information Technology, and the third one is Legal. Six Sigma projects can be undertaken in each of these aspects; depending on the kind of defects identified.

What is the benefit of Six Sigma?

It also provides proper metrics to reduce variability while executing processes to enable improvement in on-going business operations. However, there are 7 surprising benefits that Six Sigma offers that will help your organization.

How does Six Sigma help?

Six Sigma can break these barriers and empower you to specifically measure time spent on activities and identify root causes of low productivity. By collecting business critical data from various locations, Six Sigma will help you to address the real problem rather than beating around the bushes blindfold.

Why do companies use Six Sigma?

Customer satisfaction or customer loyalty is one of the significant factors that determine the success of your organization. Your customers will stay loyal to you only when there is high level of customer satisfaction for your products or services. According to latest reports, enterprises that use Six Sigma methodology achieve 40% more ROI than those who do not use the methodology. Experts believe many customers do not return to do business because of dissatisfaction with their experience or the attitude of employees. The problem is, enterprises do not even know that there is dissatisfaction among their customers and hence decreased levels of customer loyalty.#N#In this regard, Six Sigma reduces the risk of having dissatisfied customers by identifying the root cause and addressing critical attributes of customer’s perception of satisfaction towards their service / product. With the help of Six Sigma training for your key personnel, it will help you to iron out the kinks in your processes and help you to restore the customer’s confidence with better quality and service.

Why is Six Sigma important?

Six Sigma is not just a process improvement methodology; it also plays an important role providing enterprise level strategic planning. After your business has its mission statement and conducted SWOT analysis, then Six Sigma will help you to focus on areas for improvement. For example, if your core business strategy is based on providing quality services in the market, then Six Sigma can be used to improve both internal and external processes by eliminating defects in your products and provide the best of quality in terms of both product features and services. Six Sigma will help you in your organization’s journey to be the best in what it does.

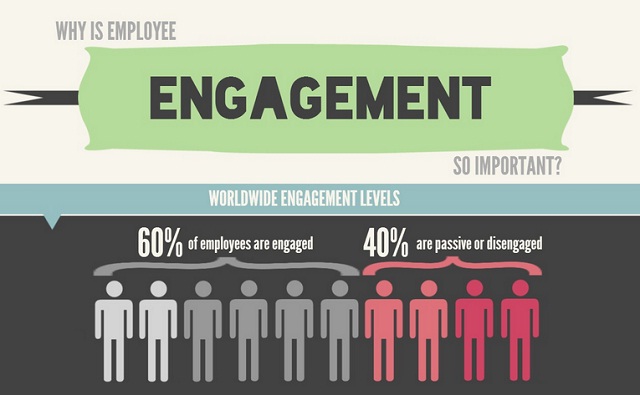

How does Six Sigma help employees?

With Six Sigma, not only your customers are highly satisfied, but your employees as well. In fact, for a business to succeed it needs the workforce to act and respond in a right way – but employees will be obliged to do so only when there is sufficient motivation. Enterprises who can properly engage their employees have achieved 25 – 50 percent more productivity on a consistent basis. Empowering your employees with Six Sigma training will help them to learn new tools and techniques which allows their professional development to create a favorable environment in an enterprise that leads to highly satisfied employees with increased motivation.